-

Email flowtechmeters@gmail.com

-

Call Now 91-9446333195

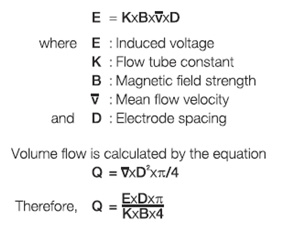

FLOWTECH’s Electromagnetic Flowmeter is based on Faraday’s Law of

Electromagnetic Induction. In an EMF meter, a magnetic field is generated in the

flow tube by a set of specially designed flow coils. As the conductive liquid passes

through this electromagnetic field, an electric voltage is induced in the liquid which is

directly proportional to its velocity and is perpendicular to both, the liquid flow

direction and the electromagnetic field direction. This induced voltage sensed by the

electrodes is sent to the Transmitter (or the flow converter) and digital signal

processing is done before the flow value is displayed in the appropriate engineering

unit on an illuminated alphanumeric LCD.

The flux density of the electromagnetic field in a given Flowmeter and the distance

between the electrodes are constant. Therefore, the induce voltage is only a function

of liquid velocity.

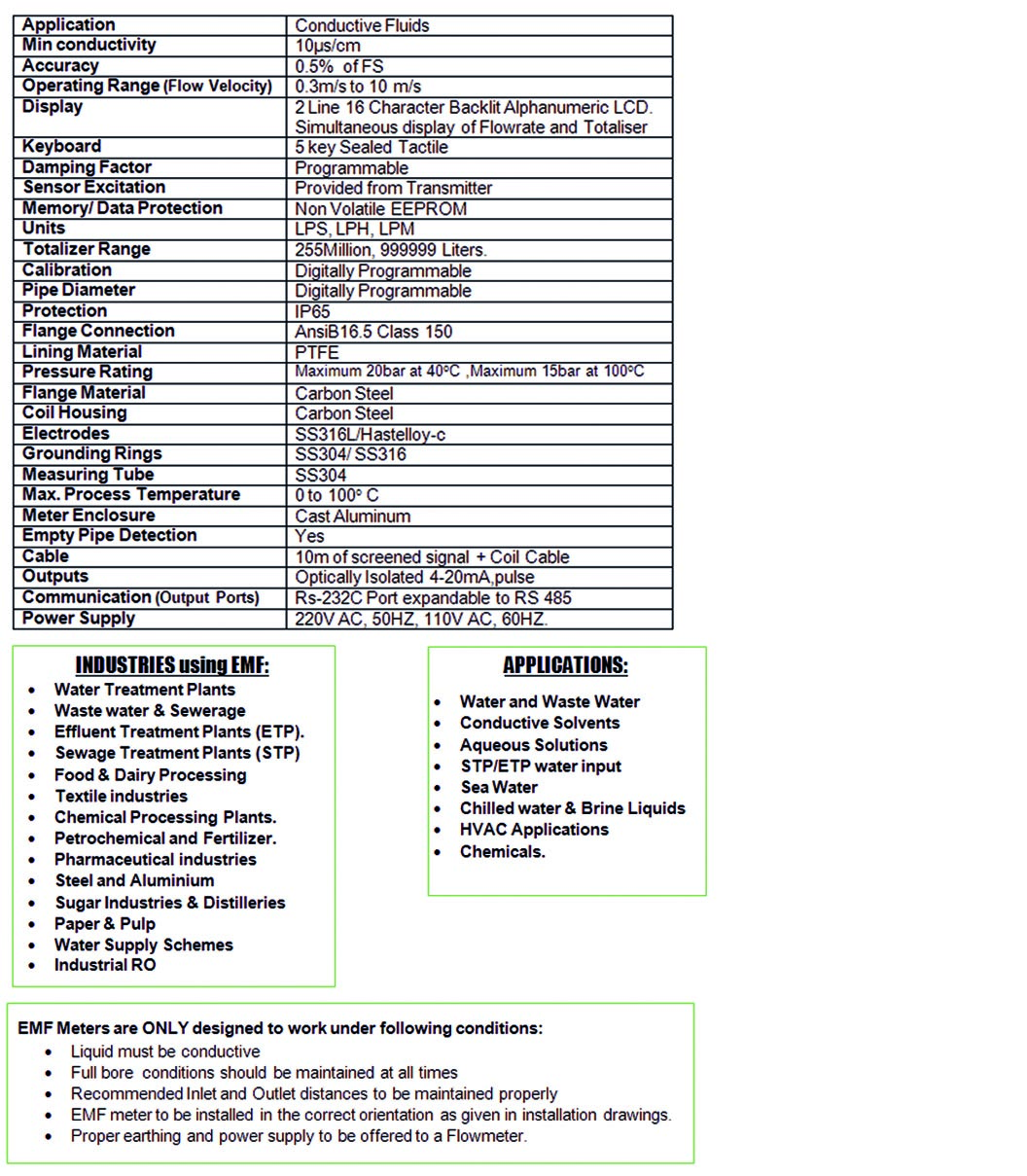

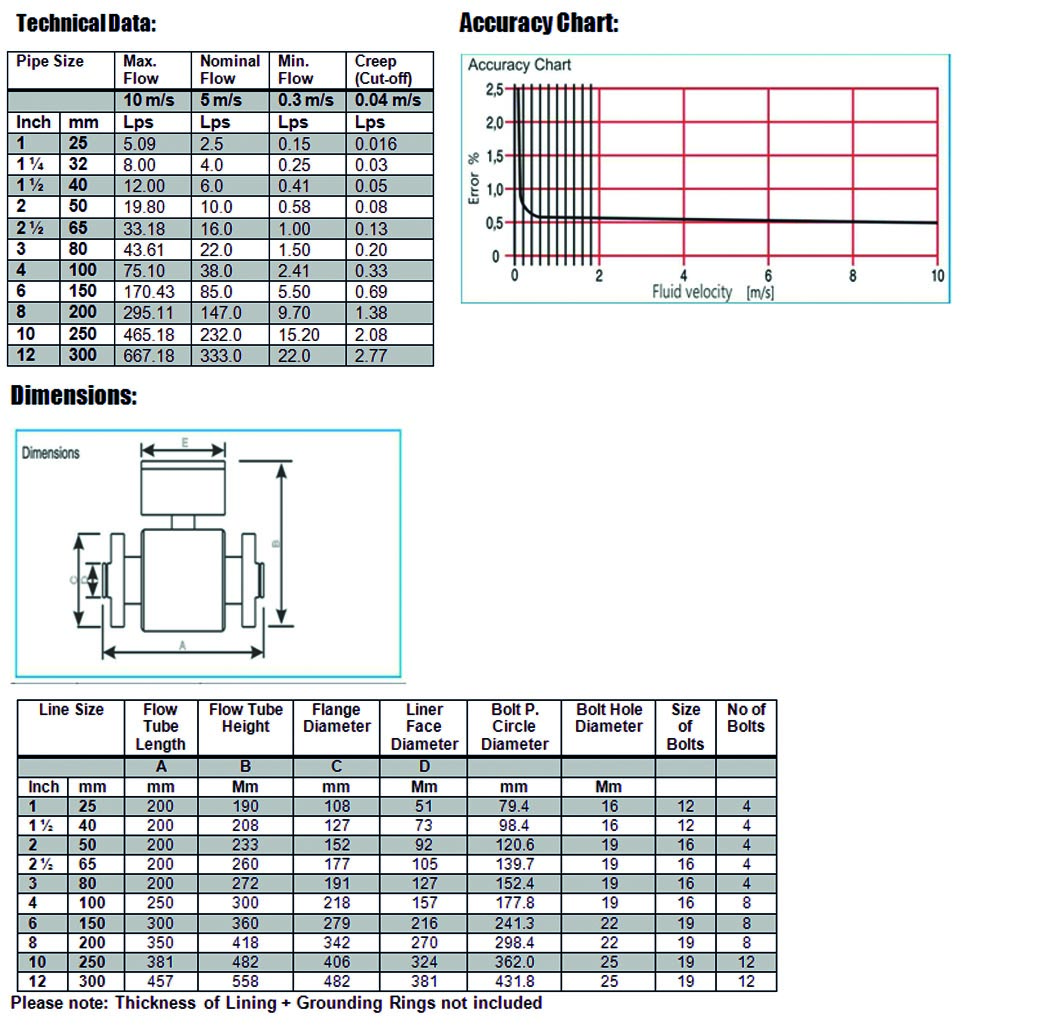

FLOWTECH Digital Flow meter uses advanced digital technology with intelligent software systems combined with precision engineering ensuring accurate and reliable flow measurement. It is used to measure any liquid having conductivity more than 10 micro Siemens/cm or Polluted/Dirty water having solid sediments. It can handle Temperature up-to 100° Celsius & performs only in full bore conditions. FMF2040 series is a fully user programmabledigital flow meter capable of measuring flow rate along with totalized flow and batching of conductive liquids.

The meter is a true volume measuring meter. The measurement is independent of viscosity, Density, Dissolved/ undissolved solids, pressure or temperature of the flowing liquid as long as it maintains certain minimum conductivity.

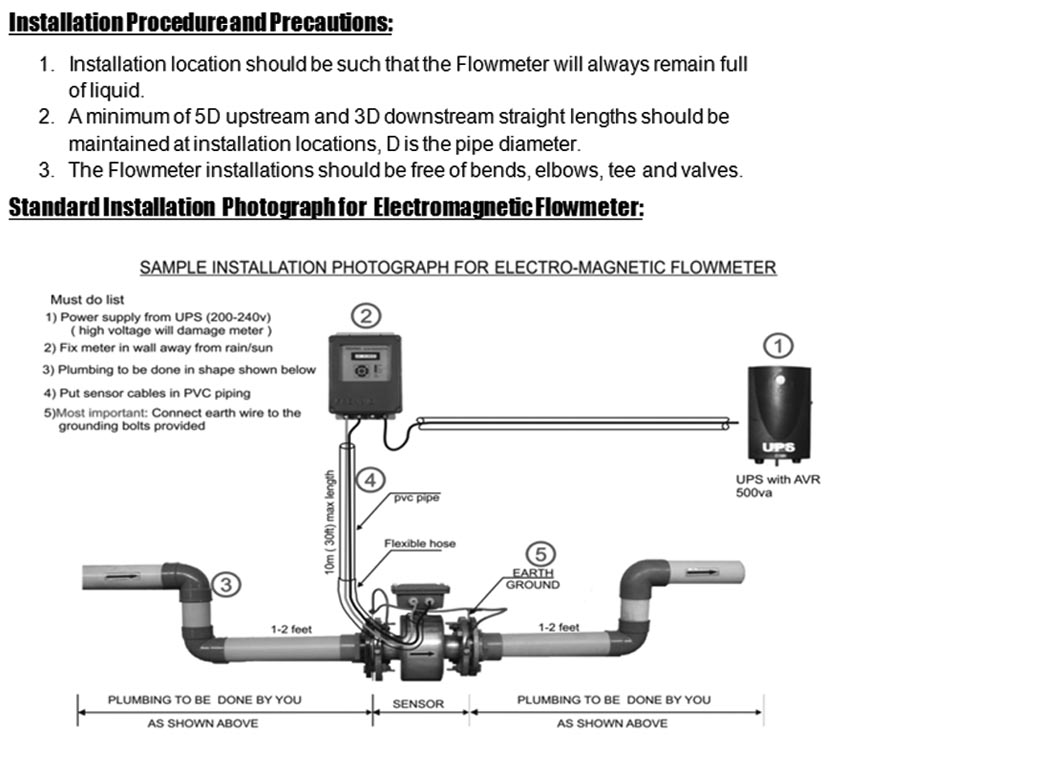

The flow meter is supplied as two components: The sensor and transmitter.

1. FLOW SENSOR: The Sensor is the unit connected in the water line.It comprises of Magnetic coils, Measuring flow tube having PTFE Liners,Sensing electrodes and process connections. Theouter body is made of Epoxy Coated Metalin fully welded construction with ANSI B 16.5 150 flanged ends. The Measuring Flow Tube is made of SS304 Material and Electrodes are made of SS316. Grounding rings are also provided on the Flanged ends for proper earthing. The induced voltage in this measuring tube converts the flow of the fluid in the pipe to an electrical signal and transmits it through a cable to the Transmitter.

2. FLOW TRANSMITTER (REMOTE DISPLAY UNIT): The second component is the FLOW TRANSMITTER, which consists of the Sensor drive and Flow computer which together acts as an Electronic Flow Convertor.The sensor drive provides the excitation voltage forthe field coils in the sensor. The Flow Computer of the Transmitter consists of microprocessor based PCB, Display with Push buttons for programming, Electrical Supply and output connection terminals.The flow computer processes and converts the measured velocity signal to actual flow and also totalizes the flow. Proper signal conditioning is done using special algorithms to compensate for undesired flow patterns. Unit contains the illuminated display and can be separated from the Sensor up-to 10 meter distance by means of wired output. It has front panel calibration, LCD display and RS232 Interface. Flow rate, Totalizer and damp functions and pulse output is also available.

All the programmable values are stored in the internal non-volatile memory. The totalized flow is also backed up in this non-volatile memory during power down, and recalled during power up. This feature enables the instrument to totalize only on the last value, and will not totalize from zero after power up. Front key panel can be used to reset totalizer to zero. The non-volatile memory is capable of storing all the user settable data and retains the data even during power down. The memory is capable of storing this data for a period of 100 years. Each data value that is being programmed is stored in a location and also in two additional backup locations.Various communication options allow the user to monitor, store, analyze the consumption at a central point on the hub, computer, web, mobile.

Our EMF Flow measurement system is manufactured using latest technology. The Microcontroller and Embedded software used in the instrument offers better accuracy and user convenience.It takes care of all your flow measurement and monitoring need with maximum efficiency.The instrument is designed to offer high flexibility with ease of operation. Most of the controls are intuitive. But some of the menu and setup should not be used without reading the operation manual.

1. Negligible Pressure Loss: There are no moving mechanical spares in the water flowing path and since it performs only in full bore conditions, hence there is no resistance to flow and the pressure drop is always negligible.

2. Ability to measure Waste Water or Liquids of any nature: Since the induced voltage is not affected bythe presence of solid impurities or any physical properties of the Liquid such as the temperature, viscosity, pressure, density and conductivity (as long as the conductivity of the measured liquid is above the minimum threshold level), hence an EMF meter can be used to measure any type of conductive Fluids accurately. But For reliable measurement, the pipe must be completely full of liquid.

3. Latest Pulsed DC Excitation:The electromagnetic field coil assembly is excited by pulsed DC technique which eliminates the interfering noise and provides automatic zero correction.

4. Maintenance Free construction because of no moving parts: the inner liners are also of long lasting PTFE lining to maximize the life of the meter.

5. Accuracy: Maintains a high accuracy level of 0.5% over a longer period of time without changing unlike mechanical meters.